Source: Armstrong Monitoring

Keep Your Environment Safe With Gas Detection Equipment From Armstrong Monitoring

Armstrong Monitoring is a leading manufacturer of high-quality gas sensing equipment. With over 40 years of experience, they remain committed to ensuring safer environments, healthier air, and reduced environmental impact. Gas detection equipment offers various benefits for your environment: life safety systems, regulatory compliance, ventilation control, energy management, and asset protection.

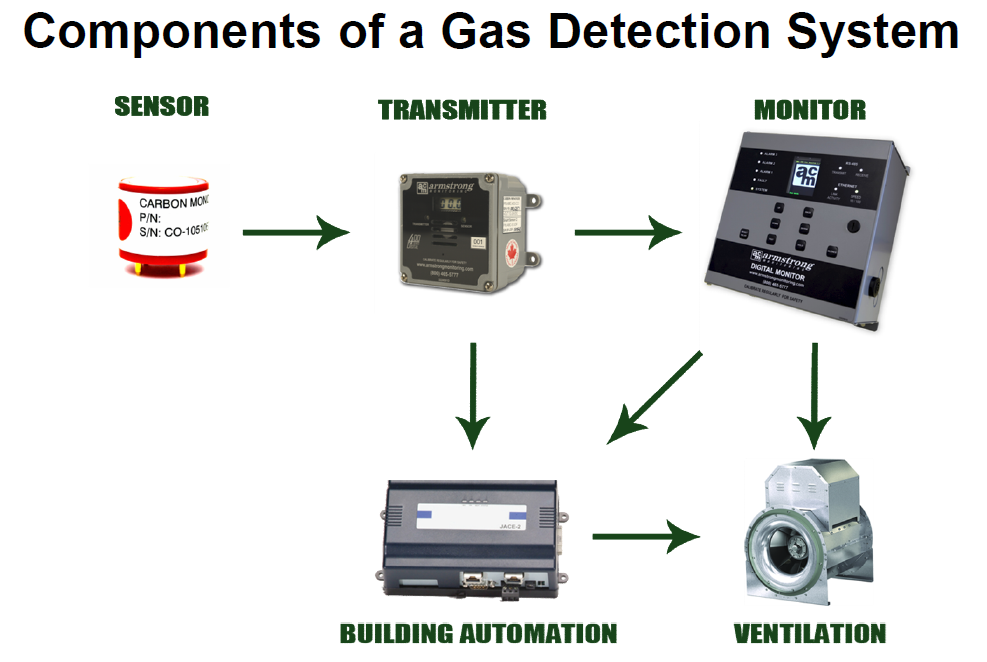

- The Sensor: determines the actual concentration of target gas in the air

- The Transmitter: conditions and normalizes output signal from sensor, typically packaged with sensor, i.e. Sensor/Transmitter

- Monitors: typically include onboard relays and audible alarm. Options such as concentration displays, audio acknowledge, and manual override switches are available

Armstrong Monitoring systems can be tailored to meet the requirements of almost any application. Armstrong Monitoring’s history and depth of product development enable their systems to support virtually every industry. Some of the most common applications for gas detection include:

- Vehicle Exhaust: Exhaust fumes emanating from fuel burning vehicles are highly toxic and can result in sickness and even death, if not ventilated properly. Vehicle exhaust produces Carbon Monoxide, Nitrogen Dioxide, and Natural Gas (found in distribution and transportation vehicles). Armstrong Monitoring’s UTX-M-400 Series transmitter is the ideal solution for parking garages, municipal works facilities, warehouses, and other vehicle exhaust applications. The integral sensor module(s) are easily changed, and are eligible for the EZ Cal service program, taking the work and risk out of maintaining your gas detection system. Visit Armstrong’s webpage for complete UTX-M-400 product information.

- Commercial Refrigeration: The release of refrigerant gases into the environment can be harmful to both the potential occupants of the space, as well as to the environment in general. In low temperature areas such as ice arenas, ammonia can be released. Refrigerants also pose the risk of displacing oxygen levels in mechanical/chiller rooms, should a leak occur. Armstrong monitoring systems can detect refrigerant gas levels and keep your environment safe. You can find a list of the most common refrigerant gases Armstrong can detect here.

- Wastewater Treatment: Growing environmental concerns have resulted in the construction and upgrading of wastewater treatment plants throughout North America. By their very design, processes involved in sewage treatment produce and use a number of highly toxic and explosive gases, requiring wastewater monitoring to ensure the safety of both employees and the environment. There are three main gases to be aware of when designing monitoring systems for wastewater treatment: Hydrogen Sulfide, Methane, and Oxygen. Learn more here.

- Battery Rooms:As lead acid batteries are charged, minute quantities of hydrogen gas are produced. Normally, the amount of hydrogen generated during charging is not of a sufficient quantity to cause concern. There are instances however, where for various reasons, hydrogen may accumulate to create potentially hazardous gas conditions. Armstrong Monitoring sensor/transmitters can be mounted to detect hydrogen levels and cause alarm or initiate ventilation if dangerous levels are reached. Find out more information on battery rooms here.

Hazardous gas levels can cause concern in many different environments, so reach out to your MAP Rep to see how Armstrong Monitoring can keep your environment safe!