Electronic Modulation

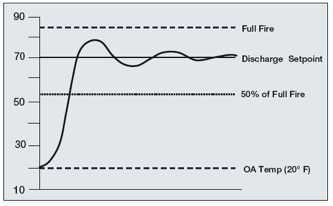

The benefit of electronic modulation is that it enables precise LAT (leaving air temperature) control. As outdoor air temperatures vary, the furnace can modulate the gas flow and deliver a constant LAT. Figure 1 below illustrates how this system would react to a start up condition at 20˚F.

Figure 1: Operation within electronic modulation range; LAT control of ±2°F

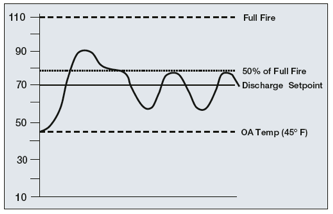

However, a potential problem exists if the modulation range has a limited turndown. Many manufacturers of indirect gas-fired MUA units only offer electronic modulation with a 2:1 turndown. This can result in the performance illustrated by Figure 2 below with the same system operating at an outdoor temperature of 45˚F.

Figure 2: Operation not within electronic modulation range; LAT control of ±10°F

The key point is that a MUA unit with electronic modulation only gives you precise temperature control when the furnace operates within its modulation range. Outside of the modulation range, the furnace will behave like a single-stage unit and deliver inconsistent LAT.

How often the MUA unit actually runs in its modulation range is dependent on the turndown ratio. Based on weather bin data analysis for a wide range of climates, the table below provides reasonable estimates.

| Turndown | “Staged” Mode Operation Time | “Modulation” Operation Time |

| 2:1 | 60% | 40% |

| 4:1 | 20% | 80% |

| 8:1 | 5% | 95% |

The solution to this potential problem is specifying a higher turndown ratio so that operation in the modulation range is maximized. Greenheck offers the highest modulation turndown ratios in the industry. The table below summarizes Greenheck’s capabilities.

| 1 Furnace | 2 Furnaces | 3 Furnaces |

| (Up to 400 MBH) | (500 – 800 MBH) | (over 800 MBH) |

| 4:1 | 8:1 | 12:1 |

Multi-Stage Control

An alternative to electronic modulation furnace control is high turndown multi-stage control. Where maximum turndown ratio is desired, multi-stage control is the answer. A single furnace MUA unit (<400 MBH) can have an 8:1 turndown ratio.

As with the electronic modulation options, the multi-stage turndown ratio offering is dependent on the number of furnaces in a MUA unit. The table below summarizes the staging available from Greenheck.

| 1 Furnace | 2 Furnaces | 3 Furnaces |

| (Up to 400 MBH) | (500 – 800 MBH) | (over 800 MBH) |

| 8:1 | 16:1 | 24:1 |

The 8:1 multi-stage system on a single furnace MUA unit will provide LAT accuracy of ± 3.5˚F across the entire range of outdoor air temperature conditions. The 16:1 (2 furnaces) and 24:1 (3 furnaces) systems will typically provide LAT accuracy of ± 2˚F.

Summary

Be sure that the turndown ratio or number of stages is clearly called out in your specification. A specification that simply states “shall have electronic modulation control” will likely result in a 2:1 turndown ratio, resulting in unsatisfactory LAT control and unhappy customers. For more information on Turndown Ratios and Make-up Air, contact your Michigan Air Products sales representative or visit the Greenheck website at http://greenheck.com/products/makeup