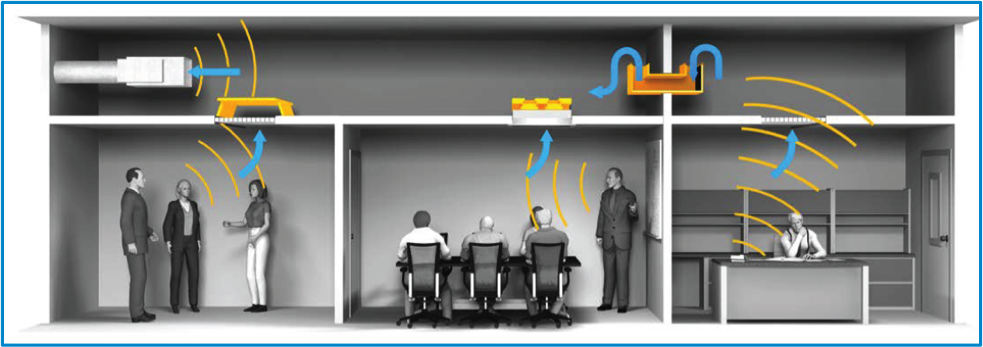

Most traditional overhead air distribution systems continue to utilize the ceiling plenum as a return air path. One of the design concerns that must be considered and dealt with is noise transfer into the occupied space from either the plenum itself or from adjacent spaces. In this brief analysis we will consider four (4) different approaches to return air grill plenum attenuation, and analyze the pros and cons associated with each.

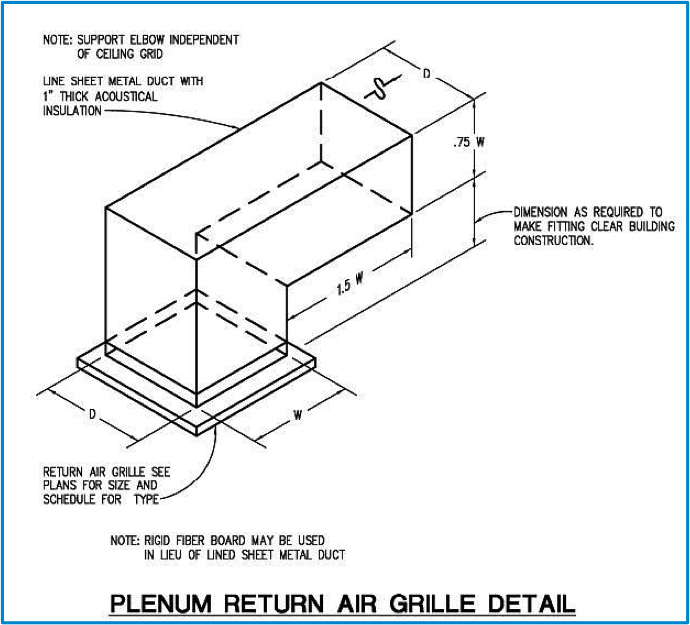

1. Contractor Fabricated Return Air Boot: The detail shown below is probably the most commonly used method of plenum attenuation at the return air grille:

The return air grill elbow is typically fabricated out of rigid fiber board, or in some cases, sheet metal lined with acoustical insulation. The resultant elbow provides some unknown level of acoustical attenuation and eliminates a direct visual path into the ceiling plenum. The elbow, due to its unequal weight distribution, must be supported from the structure above. While this elbow appears to be relatively economical, when one considers the field labor associated with installation and supporting it from above, overall fabrication and installed cost can be significant. An additional concern is the unknown or unpredictable acoustical attenuation associated with the elbow. Variation in fabrication by different contractors, variations in materials of construction, and lack of acoustical performance data are all factors that should be considered when specifying acoustical treatments for plenum return air grilles.

2. Factory Manufactured Flex Elbow: Another similar approach to the contractor fabricated elbow is the factory manufactured round flexible elbow shown below:

The flexible elbow, Flexaboot, manufactured by Thermaflex, is 60” long and available in 16” diameter. This is a relatively economical approach to plenum attenuation when utilizing a 16” diameter return air grille or a 22” x 22” neck RAG with a square to round adapter. This approach blocks direct sightlines into the plenum, but is also untested in terms of acoustical performance data. There are also CFM limitations due smaller area associated with the 16” diameter flexible dust. The flexible elbow must be supported from structure in order to maintain its 90 degree shape.

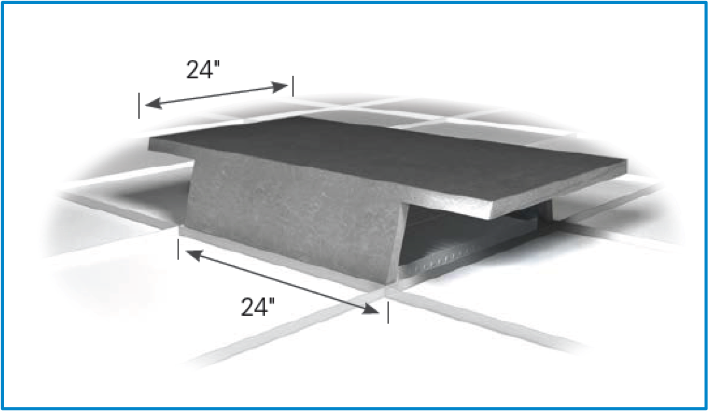

3. Return Air Canopy (RAC): Price Industries offers a great solution in terms of both acoustical performance as well as line of sight reduction. The Return Air Canopy (shown below in a 2 x 2 configuration), is available in four sizes for the most common plenum return grille applications.

Price Industries, a leading manufacturer of innovative air distribution components and engineered HVAC products, has introduced a simple, economical and tested return air silencer. The Price Model RAC or Return Air Canopy is a multifunctional product that not only reduces visibility into the ceiling plenum, but also provides excellent attenuation while maximizing airflow.

The RAC has been laboratory tested and offers excellent acoustical properties and a very economical price. Typically half the cost of a traditional acoustical elbow, the RAC is also lightweight and very easy to install.

Available in standard return grille sizes, this innovative product is now in stock at Michigan Air Products for both 2 x 2 and 2 x 1 lay-in return air grilles. Installation is a snap as the RAC is designed to match the neck size of the grille and simply snaps into place. The RAC is not required to be independently supported by structure, so installation labor is minimized.

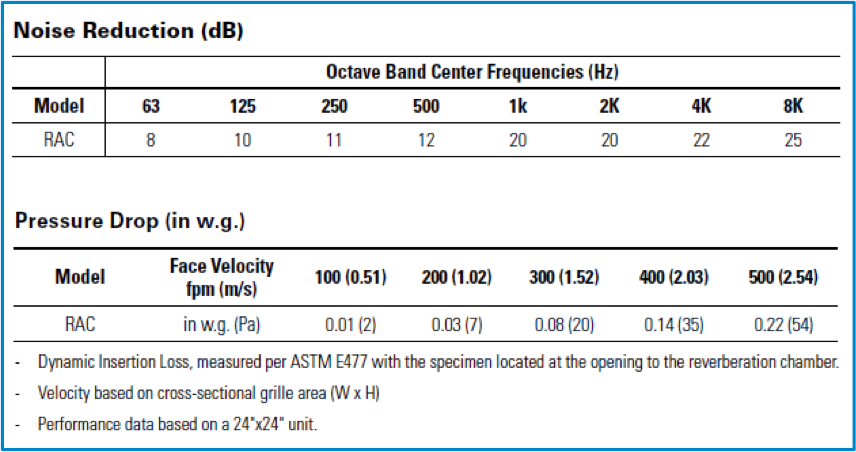

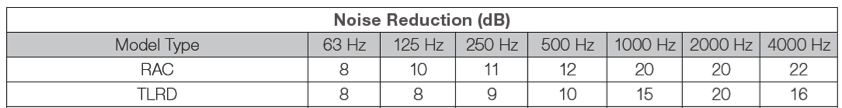

The Dynamic Insertion Loss (DIL) properties are excellent, and the RAC has been tested in accordance with ASTME477-13 in the reverberation chamber. The RAC has also been tested in accordance with UL723 and NFPA255, and bears a flame spread classification of 25 and a smoke developed rating of 50. Certified performance data is shown below:

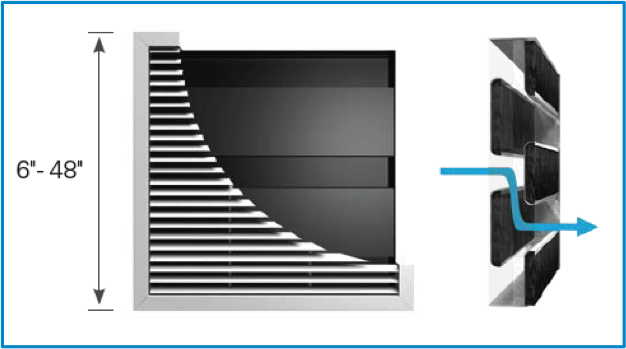

4. Thin Line Return Dissipater (TLRD): Price Industries offers another great solution in terms of both acoustical performance as well as line of sight reduction. The Thin Line Return Dissipater is available in sizes to fit any return air grille, and is also lightweight and simply sits on top of the plenum return air grille as shown below:

The TLRD and its aerodynamically designed internal geometry allows return air to flow through with minimal pressure drop and maximum attenuations. The acoustical performance is tested in accordance with ASTM E-477-13. The Noise Reduction data table below compares the performance of the TLRD and the RAC:

Conclusions

The Price models RAC and TLRD offer designers, contractors and owners an optimum choice for plenum return air attenuation. With certified acoustical performance data, these products offer the best value: a truly reliable, repeatable, and cost effective alternative to contractor fabricated products, and in stock at Michigan Air Products.

For additional information, just click Price Air Transfer Silencers, contact your Michigan Air Products salesman, or visit our warehouse.