Up until the late 1980’s, the standard metric for evaluating chiller efficiency was full load kW/ton. The HVAC industry and chiller manufacturers in particular, recognized that the full load condition is rarely encountered and that considering only the full load kW/Ton performance is a very incomplete indication of chiller efficiency.

In fact it is estimated by AHRI that chillers operate at full load only 1% of the time. Not only do chillers spend most of their operating hours running at less than full load, but also chillers with nearly the same full load kW/ton can vary substantially in their part load efficiency. To provide a better metric for rating and comparing chiller performance on an equal playing field, ARI developed and published the 1992 Version of Standard 550 which introduced the concept of the Integrated Part Load Value or “IPLV” which instead of a single efficiency at full load uses a weighted average of chiller efficiency at 25%, 50%, 75% and 100% load. The standard was substantially modified and re-issued as ANSI/AHRI Standard 550/590 1998 and has been updated several times to the current ANSI/AHRI Standard 550/590 2011.

Throughout all the revisions however the concept of IPLV has remained an integral part of the standard and is widely used when comparing the efficiency benefits of various types and configurations of chillers. While intended as a single number means of comparing individual chillers and not as an annual energy calculation tool, IPLV can be used for a quick estimate of chiller annual energy cost by using the formula of Annual Energy Cost = IPLV x $/kwh x average chiller load x operating hours but this should be viewed as only a rough estimate.

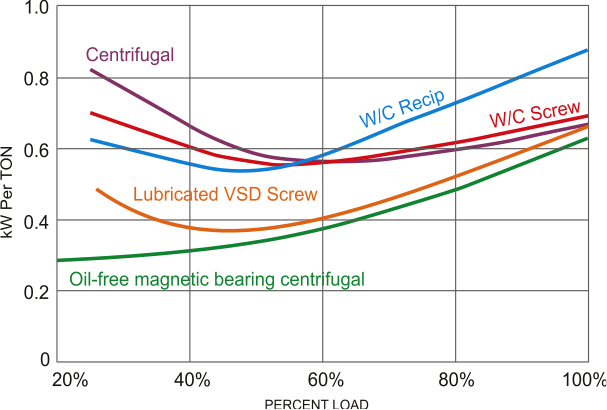

The HVAC industry’s development and widespread use of IPLV, while a step in the right direction still has drawbacks when it is used as the sole indicator of chiller efficiency, especially in regards to considering magnetic bearing, multi-compressor, variable speed chillers. In this case relying strictly on IPLV to judge chiller selections can be misleading and a complete plant hourly simulation should be used incorporating accurate modeling of chiller performance at all conditions of load and condenser water temperatures to quantify and take full advantage of the benefits of Smardt’s ultra-efficient, oil free, magnetic bearing chillers such as shown below.

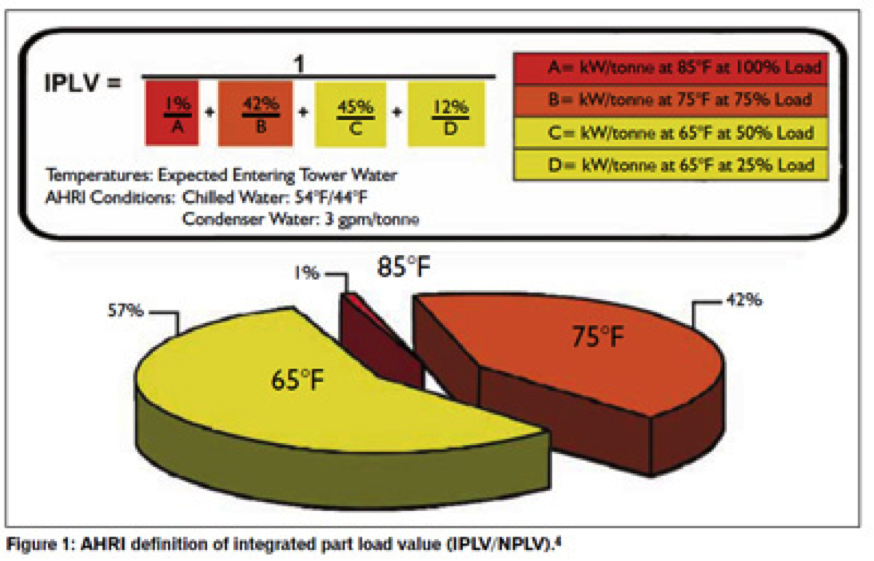

To understand some of the limitations of IPLV, one must understand exactly how the IPLV is determined and assumption behind it. The equation for IPLV is:

IPLV = 1 / (0.01/A + 0.42/B + 0.45/C + 0.12/D) where:

A = kw/ton at 100% load

B = kw/ton at 75% load

C = kw/ton at 50% load

D = kw/ton at 25% load

The decimals of “0.10”, “0.42”, “0.45” and “0.12” are therefore the weighting given to the efficiencies at 100, 75, 50 and 25 percent load. Furthermore, the kw/ton at the different percentages of load is determined assuming condenser water relief i.e. at lower percentages of load it is assumed that the outdoor conditions will allow the condenser water also to be lower than design . Lastly IPLV assumes that primary condenser water and chilled water flow rates are constant at 3 GPM per ton and 2.4 GPM per ton respectively and that a constant chilled water temperature of 44F is maintained.

Unless an actual project mirrors these assumptions, there are inherent drawbacks to relying solely at IPLV. Perhaps the most important consideration is the weighting given to the 75, 50 and 25 percent load conditions. A project’s actual building hourly load profile may result in substantially more hours of load below 60% than what the IPLV is based on. As illustrated below, for a chiller utilizing 3, 4, 5 or even 6 smaller compressors on a single shell, the kW/ton at low load can be extremely low compared to a single large centrifugal compressor and the full benefit of this may not be accurately considered using IPLV especially if the plant spends more time below 60% load than the weighting given by IPLV allows for.

Likewise, IPLV is also designed to evaluate single chiller installation only and these weighting factors would not be accurate for most multi chiller applications. Secondly different compressor designs and refrigerant metering methods may allow more aggressive condenser water relief at low load than what is built into the AHRI IPLV conditions. Smardt chillers can operate with as low as 55F entering condenser water and IPLV is based on assuming only 65 Fentering condenser water at 50% and 25% load. It should be noted that AHRI does allow for deviation from their standard conditions via an alternative to the IPLV, called NPLV however, while the NPLV may allow different conditions to be used, it still is not as accurate of a comparison tool as an hourly building simulation model and the weighting and percentages of load for NPLV remain the same as IPLV.

Even when doing an hourly building simulation of chiller options, it is important to understand how the input data is used by the software program especially if a chiller manufacturer’s simulation program is used. Many of these programs have the user fill out a table of chiller performance and then calculate the performance from the table inputs. For instance Trane Trace has an option to either fill in a performance table or use an equation. The performance table is then used to calculate chiller performance at other conditions of load and condenser water temperature. Whereas the calculation methodology may be accurate for a single compressor Trane centrifugal chiller, it may not be truly representative of a multi-compressor variable speed magnetic bearing chiller’s performance. Consequently the simulation programs predicted chiller performance at conditions outside the table inputs should be compared to the actual manufacturer’s chiller performance runs at the same conditions to see if the model is truly accurate or, often the better alternative is to use the user defined equation option. Smardt and Michigan Air Products can assist in the development of a proper equation.

Energy savings is normally the driving force behind the decision to investigate and use magnetic bearing chillers on a project. However there are also advantages beyond just what the electrical savings may be. Oil free magnetic bearing chillers with multiple compressors may allow redundancy with fewer chillers, may result in lower annual maintenance and repair costs, will not have performance degradation over time due to excess oil content in the refrigerant, and may allow for smaller or more flexible foot prints and the use of “split” chillers such as shown below for limited access retrofit projects. All of these factors should be considered in addition to IPLV or NPLV and may substantially affect the installed cost and overall life cycle cost.

For years the HVAC industry has struggled to find easier ways to quickly evaluate the performance of chillers and central chilled water plants. With accelerating pressures to increase design productivity, the desire grows stronger for a quick, simple and accurate evaluation tool to analyze chiller plant performance. This demand for quick results has led many to in the HVAC industry to use single number evaluation methods such as IPLV as a substitute for executing a complete hour by hour modeling analysis. However decisions based on this simplified data can result in a poor prediction of energy equipment use so it is important to use a more accurate energy analysis tool to ensure optimal solutions especially when evaluating newer chiller technologies such as oil free, magnetic bearing chillers.

For additional information, please contact your Michigan Air Products salesman or visit http://www.smardt.com/